Volume 13 - Year 2025 - Pages 90-100

DOI: 10.11159/ijepr.2025.011

Nature-Based Solutions to Rehabilitate Erosion Processes in a Brazilian Urban Settlement

Camila Xiomara Meza-Cuenca1, Giancarlo Rodrigo Vargas-Jimenez2, Jorge Antonio Corzo-Chavez3

1,2,33Carrera de Ingeniería Industrial, Universidad de Lima, Perú 15023

120201361@aloe.ulima.edu.pe, 220202186@aloe.ulima.edu.pe,

3jacorzo@ulima.edu.pe

Abstract - This research project addressed the high defect rate in a Peruvian textile SME through the implementation of three Lean Manufacturing tools—5S, SMED (Single-Minute Exchange of Dies), and Standardized Work—alongside an environmental assessment using the Leopold Matrix. The main objective was to reduce production defects and improve operational efficiency without negatively impacting the environment. The 5S implementation led to a significant improvement in workplace organization, increasing the evaluation score from 32.35% to 72.06%. SMED reduced setup time to 148.26 minutes, while Standardized Work improved efficiency from 96.69% to 97.69% and lowered the defect rate from 2.65% to 1.64%. Environmentally, the net impact value improved significantly, from an initial score of -258 to -14, reflecting a substantial reduction in environmental impact. These results demonstrate that operational performance and environmental sustainability can be jointly enhanced in resource-constrained manufacturing settings.

Keywords: : 5S methodology, Single-Minute Exchange of Die, Standardized Work, environmental impact, textile, defectives.

© Copyright 2025 Authors - This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2025-01-25

Date Revised: 2025-09-25

Date Accepted: 2025-11-10

Date Published: 2025-12-22

1. Introduction

Defective production refers to the proportion of products that fail to meet established quality standards during the manufacturing process due to factors such as machinery performance, operator proficiency, raw material quality, and environmental conditions [1]. In the textile industry, the rate of defective products varies based on the type of fabric produced and the complexity of the associated production processes. According to industry standards [2], acceptable defect rates in textiles typically range from 0% for critical defects to 2,5% for minor ones. However, actual defect rates often exceed these thresholds due to inefficiencies within production systems.

A recent assessment of textile production in Peru highlights that local small and medium-sized enterprises (SMEs) experience elevated defect rates, which adversely affect their productivity and profitability. In a specific SME analysed, the defect rate for fabric production stands at 2,38%, mainly attributed to inefficiencies in the weaving process and insufficient quality control measures [3]. This company specializes in the production of knitted fabrics, including jersey and ribbed textiles, operating 12 circular machines, and employing over 20 staff members.

Based on the work of Meza-Cuenca et al. [4], this study further explores the integration of Lean and sustainable practices in textile manufacturing, adapting, and extending their methodological framework to a Peruvian SME context.

Technological innovations go hand in hand with environmental responsibility in the textile industry. Although other industries may generate higher emissions, it is crucial for textile companies to contribute to sustainability. Through simple practices such as waste reduction, a positive impact can be achieved.

This study aims to implement Lean Manufacturing tools—specifically SMED, standardized work, and 5S—to reduce the defect rate in this SME. The objectives include identifying critical inefficiencies within the production process, implementing targeted improvements, and evaluating their effects on defect reduction, productivity enhancement, profitability improvement, and environmental sustainability. It is anticipated that these measures will not only decrease waste and optimize resource utilization, but also minimize the environmental footprint of production and reinforce the company’s competitive position in the textile industry.

2. State of art

A systematic review of relevant studies was conducted, identifying 400 articles, with 40 selected for detailed analysis. Of these, 34 were deemed highly relevant for the project. Several studies demonstrated the impact of Lean Manufacturing tools on operational efficiency. Amiel-Reategui et al. [5] found that SMED reduced machine downtime by 23%, cut set-up times by 35%, and improved OEE (Overall Equipment Effectiveness) from 46,90% to 60,18%, leading to a reduction in defects.

Sharma and Lata [6] showed that implementing 5S increased efficiency from 67% to 88,8%. Makwana and Patange [7] reported a 64% increase in productivity and a 35% boost in operational efficiency with 5S. Aucasime-Gonzales et al. [8] demonstrated a 13% improvement in production efficiency and a 22,5% reduction in setup times using Lean Manufacturing and Lean Maintenance.

Jiménez et al. [9] applied TPM, SMED, and Work Standardization, increasing machine availability from 80% to 93%, reducing set-up time from 56,25 minutes to 22,30 minutes, and cutting annual breakdowns from 190 to 135. Lastly, Alcazar-Zamora et al. [10] found that SMED, Standardized Work, and TPM reduced waste by 25% (from 5,77% to 4,33%) and increased OEE from 42,29% to 61,53%. These studies emphasize the substantial influence of Lean tools in enhancing efficiency and minimizing waste across different industries.

3. Methodology

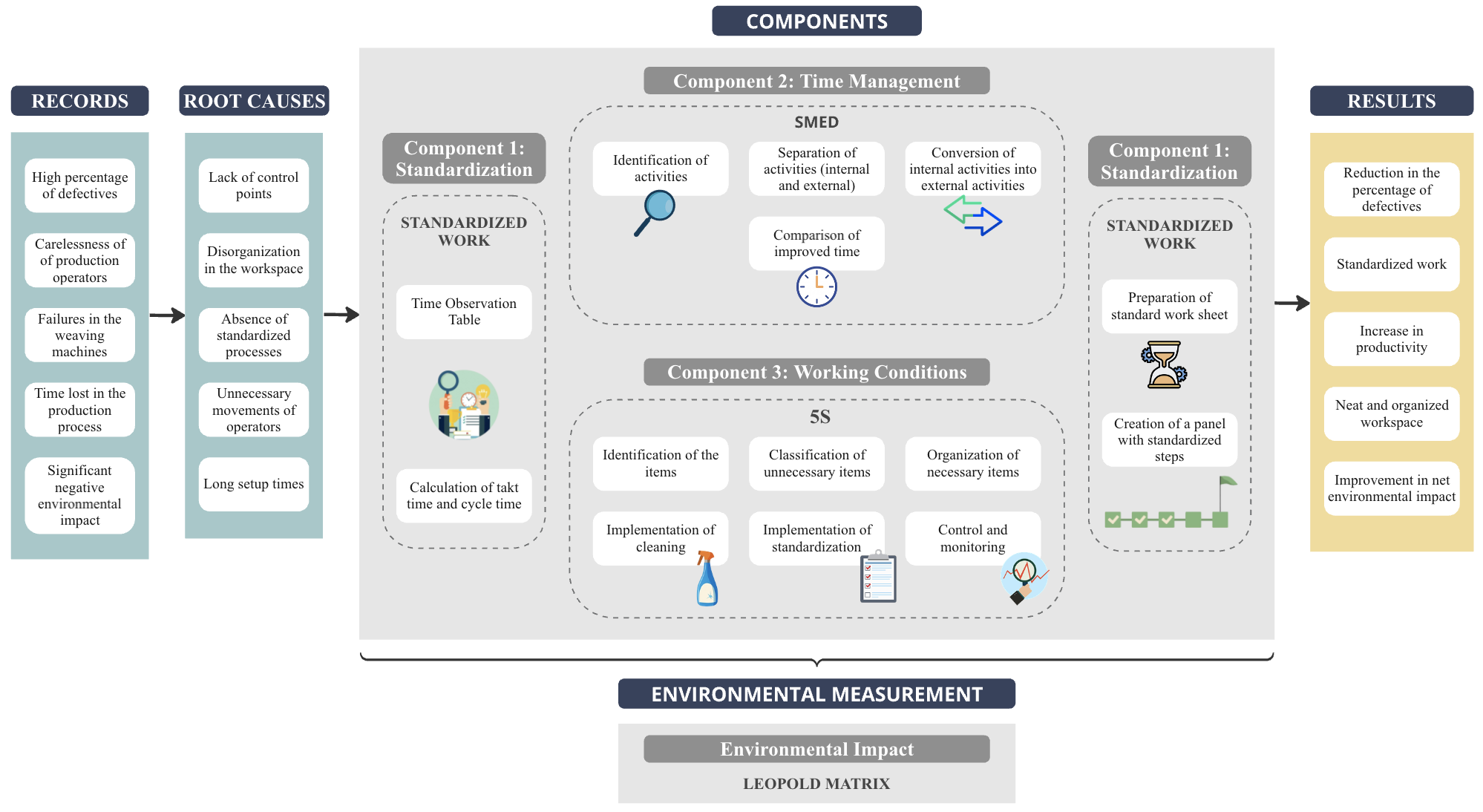

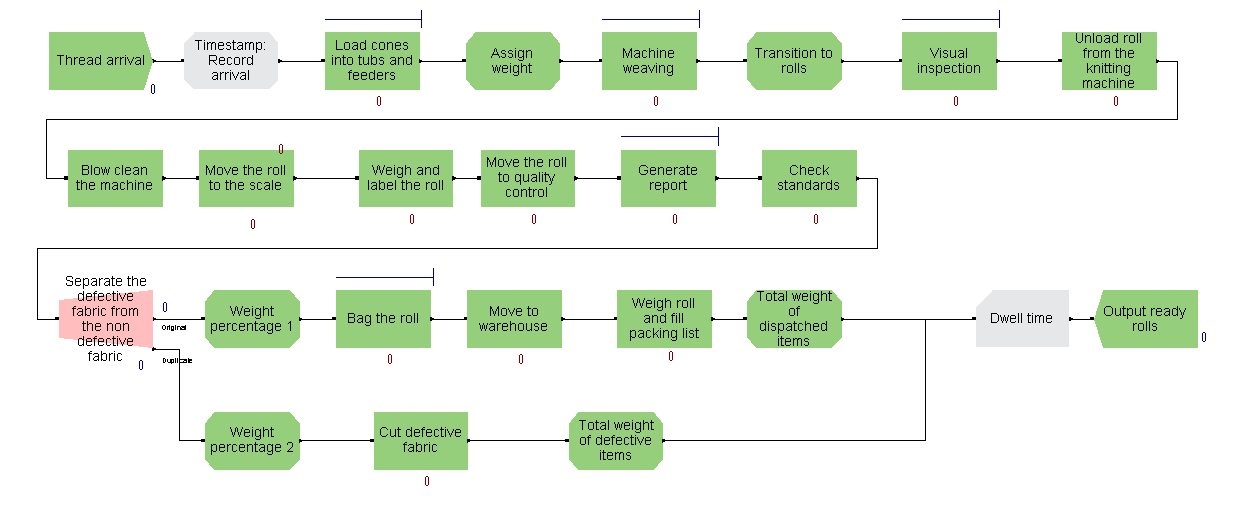

This research adopts an explanatory and correlational approach, as it seeks to identify the primary causes underlying the problem identified in the company. Additionally, the study is quantitative in nature, utilizing numerical data to measure variables and indicators. Independent variables, such as delays in fault detection and fabric production times, have been determined, while the dependent variable is the high percentage of defectives in the production process. Figure 1 provides an overview of the records, the implementation process, and the projected outcomes.

The graph shows the company’s operational records and their root causes, which led to the decision to implement the improvement tools Standardized Work, SMED and 5S, together with an environmental assessment, with the aim of reducing operational issues, particularly the high percentage of defective products.

3.1. Component 1: Standardized Work

Standardized work is a Lean Manufacturing tool that focuses on establishing a structured and repeatable sequence of operations to ensure consistency and efficiency in production processes. It helps minimize variability, reduce waste, and improve workplace organization. According to Fin et al. [12], standardized work optimizes task execution and enhances productivity by promoting uniformity in operational processes.

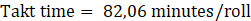

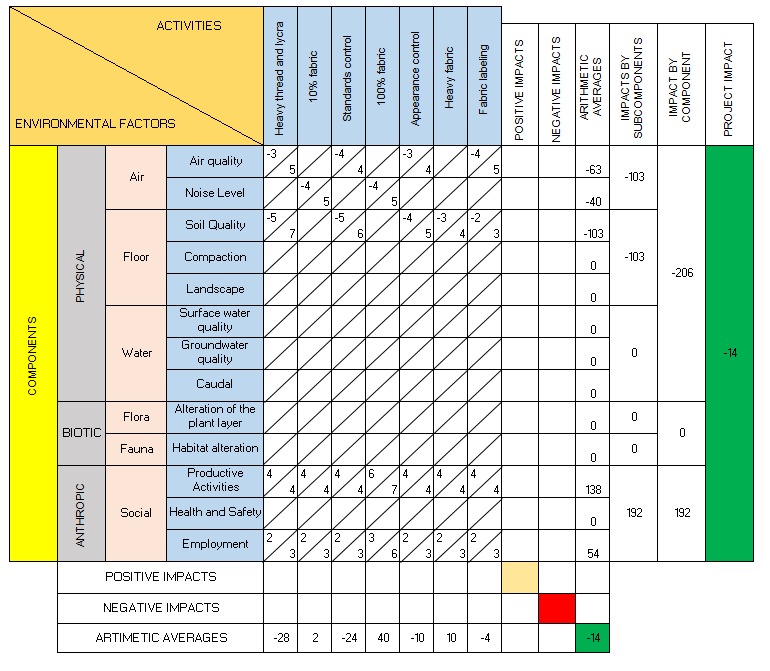

As the first step in implementing standardized work, the takt time was calculated as shown in Eq. 1, using the following data:

- Daily available time: 4,185 minutes

- Daily demand: 1,275 kg = 51 rolls

Since the calculated takt time is 82,06 minutes/roll and the cycle time before the improvement was 101,97 minutes/roll, changes to the production line are required. Consequently, the SMED and 5S tools were implemented to reduce time and improve activity organization. As the last step, after implementing these tools, the standardized work sheet was created.

3.2. Component 2: SMED

SMED is a tool that helps reduce machine setup and changeover times, improving production flexibility and minimizing downtime, which leads to enhanced productivity. According to Vieira et al. [13], SMED methodology focuses on categorizing setup activities into internal tasks, which require machine stoppage, and external tasks, which can be performed while the machine is still operating. The goal is to convert as many internal tasks as possible into external ones, thereby significantly reducing the time needed for equipment changeovers and improving overall production efficiency.

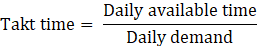

As illustrated in Figure 2, the process of implementing this tool starts with identifying the activities within the production process. Then, the factors contributing to inefficiencies are examined, and simulations of both the initial and optimized scenarios are conducted using the Arena software.

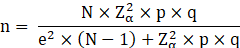

The population (N) was determined based on the approximate annual fabric production of 52 425 rolls for 2023, the year prior to the start of the improvement implementation. A maximum allowable margin of error of 0,05 and a confidence level of 95% (Z = 1,96) were used. Additionally, data heterogeneity of 50% was assumed, and the sample size was determined using the Eq. 2.

A sample of 382 rolls was taken, with each roll weighing 25 kg, totaling 9550 kg of material entering the system.

3.3. Component 3: 5S

5S is a Lean Manufacturing tool that enhances workplace organization, cleanliness, and productivity by establishing an efficient and structured environment. It helps reduce waste, improve safety, and boost employee morale. The implementation of 5S leads to better resource utilization, reduced downtime, and increased productivity, while fostering a culture of continuous improvement. According to Kuchekar et al. [14], 5S consists of five steps:

- Seiri (Separate): Items in the workplace are categorized, and unnecessary items are removed to create more space and improve efficiency.

- Seiton (Order): Items and equipment are organized and placed in specific locations to ensure they are easy to find and use.

- Seiso (Cleaning): Regular cleaning of the workplace and equipment is performed to maintain a safe and tidy environment.

- Seiketsu (Standardize): Standard procedures and rules are developed and maintained to ensure the workplace remains organized and clean.

- Shitsuke (Discipline): Employees adhere to the established practices, ensuring the consistent application of the 5S principles. This methodology includes an improvement plan consisting of an initial audit, implementation of the 5S steps, and a final audit.

Additionally, as part of the tool's implementation, an audit format in the form of a questionnaire was developed. This was applied at the beginning and end of the process to evaluate the improvements achieved and is also conducted monthly to ensure continuous improvement. The questionnaire has a maximum score of 68 points, with each question assessed on a scale from 0 to 4, where 0 represents poor performance and 4 represents excellent performance.

This format includes specific questions for each "S," allowing verification of compliance and calculation of a total score that reflects the level of tool implementation.

3.4. Environmental measurement

Environmental sustainability plays a pivotal role in the textile industry, requiring the adoption of responsible practices across all stages of production. As an initial step, our processes are examined through a diagram encompassing inputs, outputs, environmental aspects, and impacts, which enables the identification of critical areas for improvement and the development of strategies aimed at minimizing ecological impacts. In alignment with current regulations and guided by a sustainable perspective, this approach seeks to foster a more responsible future for both the industry and society. The Table 1 presents the diagram used to analyze each stage of the production process.

Table 1: Environmental aspects and impacts diagram.

|

Input |

Process Stage |

Output |

Environmental Aspects |

Environmental Impacts |

|

Yarn 30/1 and Lycra 20/DE |

Weighing of yarn and lycra |

Weighed yarn ready for knitting |

Generation of waste or packaging from yarn |

Indirect atmospheric and soil contamination |

|

Weighed yarn |

Knitting at 10% |

Initial knitting at 10% |

Possible emissions associated with energy consumption |

Microfiber pollution and possible health deterioration |

|

Knitted at 10% |

Standard control |

Compliant fabric and non-compliant material |

Generation of solid waste from non-compliant materials |

Soil and water contamination |

|

Compliant material (knitted at 10%) |

Knitting at 100% |

Knitting completed at 100% |

Possible noise or heat emissions |

Noise pollution and health deterioration of personnel |

|

Knitted at 100% |

Appearance control |

Compliant and non-compliant fabric |

Generation of textile waste |

Soil, water, and indirect atmospheric contamination |

|

Compliant fabric |

Weighing of fabric |

Weighed fabric ready for labeling |

Generation of waste and heat emissions |

Soil contamination and exposure to heat |

|

Weighed fabric |

Fabric labeling |

Labeled Jersey fabric roll |

Generation of toxic waste |

Chemical contamination and health deterioration of personnel |

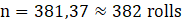

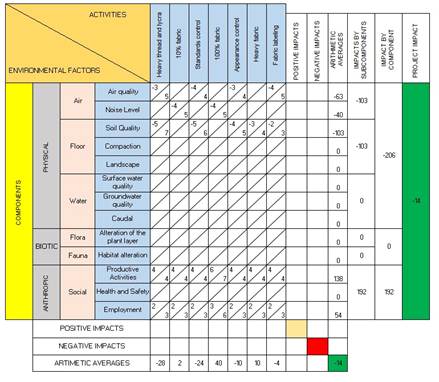

On the other hand, the Leopold Matrix is an environmental assessment tool that enables the analysis and quantification of impacts associated with the activities of a production process. After developing a detailed diagram that identifies inputs, outputs, environmental aspects, and impacts in the weaving process of a textile company, the application of this matrix allows for a deeper identification of the most significant impacts.

Through a systematic approach, the matrix helps to classify and evaluate both the magnitude and significance of each environmental impact, facilitating the prioritization of corrective or preventive actions. In this way, the company can manage its relationship with the environment more effectively, optimizing environmental performance and minimizing negative effects on ecosystems.

To conduct the impact assessment for each environmental factor, the following criteria are considered:

- Magnitude (M): Refers to the affected area or volume, measured on a scale from 1 (lowest) to 10 (highest).

- Importance (I): Refers to the relevance of the effect, also measured on a scale from 1 (lowest) to 10 (highest).

In the evaluation table, values are assigned as follows: the left column records the magnitude score, which may be positive to indicate a beneficial impact or negative to denote an adverse impact. The right column records the importance of the score, applying the same criterion. Figure 3 presents the results of the assessment carried out prior to the application of the proposed tools.

In the initial assessment, the environmental impact was found to be negative, with a highly unfavorable value of -258, where the main effects were identified in air and soil. These impacts stem from the vapors generated by the weaving machines, which also contribute to soil contamination through the textile residues produced during the process. Additionally, in the social dimension, a positive impact was observed, although to a lesser extent, since the increased amount of waste in the process reduces operator productivity by creating a disorganized and unhygienic work environment.

4. Results

For the improvement process and the implementation of the tools, training was first provided to the workforce on the tools, which allowed for a better understanding of them and thus enabled satisfactory results.

Upon the implementation of the SMED tool, the results from the base model and the improved model are presented in Table 2 to facilitate comparison and determine whether an improvement was achieved.

Table 2. Comparison of results (Base-Improved).

|

Indicator |

Base |

Improved |

Units |

|

Indicator 1 (Total weight of defective items) |

313,24 |

162,35 |

Kg |

|

Indicator 2 (Total weight of dispatched items) |

9236,70 |

9387,60 |

Kg |

|

Dwell time |

157,42 |

148,26 |

Min |

|

Roll time in the process |

79,05 |

74,47 |

Min |

As seen in the table, the results of the improved model reflect positive progress in all indicators compared to the base model, confirming that the application of the tool achieves its objective.

The application of the 5S tool consisted of carrying out each of the predefined "S" steps. As depicted in Figure 4, photographs were taken to document the implementation process and highlight the improvements made, comparing the initial state with the enhanced condition.

After completing the final audit, remarkable results were achieved, as detailed in the table. Table 3 shows a total score of 49 and a percentage of 72,06%. This progress represents a 50,10% percentage increase, reflecting a significant improvement compared to the initial audit results, demonstrating the correct use of the tool and the continuous efforts of the production operators.

Table 3. Initial audit - Final Audit.

|

Initial Audit |

Final Audit |

% Increment |

|||

|

Order |

Score |

% |

Score |

% |

|

|

1°S |

8 |

36,36% |

10 |

45,45% |

20,00% |

|

2°S |

5 |

22,73% |

15 |

68,18% |

66,67% |

|

3°S |

7 |

31,82% |

9 |

40,91% |

22,22% |

|

4°S |

2 |

9,09% |

9 |

40,91% |

77,78% |

|

5°S |

0 |

0,00% |

6 |

27,27% |

100,00% |

|

Total |

22 |

32,35% |

49 |

72,06% |

55,10% |

Also, the standardized work sheet was completed, as shown in Figure 5.

Finally, the environmental assessment was conducted following the implementation of the tools to compare the results with the previous evaluation and to confirm whether their application resulted in a positive impact. This assessment is presented in Figure 6.

As can be observed, the matrix reveals a negative environmental balance in the textile process, with a total net impact of -14, representing a substantial improvement compared to the previous result of -258. This outcome suggests that the corrective measures and tools applied were effective in mitigating a significant portion of the adverse effects previously identified. The greatest negative impacts continue to be associated with air, soil, and water quality, mainly because of energy consumption and waste generation during the weaving process and standards control stages. However, it is important to highlight that, although these impacts persist, their magnitude and significance have decreased notably, indicating progress in environmental performance.

For instance, the reduction in emissions associated with vapor generation from weaving machines reflects an improvement in air quality management. Similarly, the decrease in textile waste demonstrates better control over solid residues, reducing the burden on soil and waste disposal systems. In the case of water, the optimization of cleaning and maintenance practices has contributed to lowering the risks of contamination, even though the textile process is inherently water intensive. These improvements are not absolute but rather incremental, and they highlight the value of continuous monitoring and the gradual implementation of best practices.

Subsequently, a final comparison was carried out using the indicators previously established as evaluation points. This comparison helps to identify and confirm that the application of the proposed tools improves the defined indicators. Table 4 presents the indicators obtained before the implementation of the tools and contrasts them with the new values derived from the simulation.

Table 4. Indicator traffic lights.

|

Tool |

Indicator |

Unit |

Traffic Light Classification |

As is |

To be |

Achieved |

||

|

Red |

Yellow |

Green |

||||||

|

Lean Philosophy |

Total productivity |

<0,95 |

0,95-0,97 |

>0,98 |

0,97 |

0,98 |

0,98 |

|

|

SMED |

Total production time |

Min |

>170 |

170-150 |

<150 |

157,42 |

150 |

148,26 |

|

Standardized Work |

% Efficiency |

% |

<90% |

90%-97% |

>97% |

96,69% |

98,00% |

97,69% |

|

% Defective products |

% |

>3% |

3%-2% |

<2% |

2,46% |

1,50% |

1,64% |

|

|

5S Method |

5S Compliance |

% |

<50% |

45%-80% |

>80% |

32,35% |

86,76% |

72,06% |

|

Matrix Leopold |

Environmental impact score |

- |

<-100 |

-100 to -20 |

>-20 |

-258 |

-20 |

-14 |

Some of the results obtained exceed the forecasted values, such as total productivity or total production time, while one is close to the target value. Nevertheless, it is confirmed that they have a positive impact on the goal, which is the improvement of these indicators through the application of the proposed tools.

Finally, after conducting the economic flow of the company, the results presented in Table 5 were obtained.

Table 5. Economic evaluation indicators.

|

Indicators |

Results |

|

NPV |

$ 11 924,87 |

|

IRR |

48,36% |

|

Cost-benefit |

2,37 |

|

Payback |

3,74 months |

On the other hand, the implementation of Lean tools generated significant environmental benefits. By reducing production times and decreasing the percentage of defects, the use of energy and materials was optimized, thereby reducing indirect carbon emissions associated with energy consumption. This impact is particularly relevant in a context where environmental sustainability is a priority.

Additionally, the reorganization of the workspace through the 5S methodology fostered a cleaner and more organized environment, reducing the generation of solid waste and promoting recycling practices such as recycling thread cones and boxes. This not only reduced the direct environmental impact but also promoted a culture of sustainability among the workers, who actively participated. The decrease in waste and the optimized use of resources produced an immediate positive effect, while also establishing a stronger foundation for a more robust production system. These improvements reduced the environmental footprint of the production process, paving the way for a more sustainable and competitive model over time.

On the positive side, the assessment underscores significant contributions in the social dimension. Improvements were observed in working conditions, as a more orderly and hygienic environment enhanced operator productivity and reduced risks related to occupational health. Moreover, the matrix indicates that the process contributes to the promotion of productive activities and the creation of employment opportunities. These outcomes reveal the dual nature of sustainability in the textile industry: while environmental costs remain an important concern, social benefits cannot be overlooked, as they strengthen the relationship between the company, its workforce, and the broader community.

When comparing both evaluations—before and after the application of environmental tools—it becomes clear that the adoption of systematic approaches, such as process standardization, waste segregation, and energy efficiency measures, is essential for reducing environmental burdens. The first evaluation presented a scenario of high environmental vulnerability, where the company was at risk of compromising both its ecological footprint and its social responsibility. In contrast, the second evaluation, although still showing a negative balance, demonstrates that structured interventions can lead to measurable improvements in sustainability indicators.

This contrast emphasizes a crucial point: sustainability in industrial contexts cannot be achieved overnight but rather through progressive and iterative processes of improvement. The Leopold Matrix, in this regard, serves not only as a diagnostic tool but also as a framework for continuous evaluation. Its application before and after the intervention allows for quantifying changes and, most importantly, identifying residual impacts that require additional attention. Therefore, the results invite reflection on the need to integrate mitigation strategies into the company’s long-term management plans, such as investment in cleaner technologies, enhanced energy efficiency systems, and circular economy practices that enable the reuse or valorization of textile residues.

Although the textile process still presents a net environmental cost, the evidence demonstrates that the implementation of corrective and preventive tools has effectively reduced the overall impact. The shift from -258 to -14 reflects a transformation not only in environmental performance but also in organizational culture, where sustainability begins to be perceived as an integral component of production rather than an external requirement. Future efforts should focus on deepening this cultural change, consolidating the environmental management system, and promoting innovation in production techniques. By doing so, the company will not only minimize its ecological footprint combination but also strengthen its competitiveness and social legitimacy in an industry that faces increasing pressure to align with sustainable development goals.

5. Discussion

The implementation of Lean Manufacturing tools has demonstrated significant improvements in key performance indicators within the company under study, not only in terms of productivity but also in environmental performance. This dual approach is especially important today, as industries must find ways to be both efficient and environmentally responsible. Lean Manufacturing, through tools such as SMED, 5S, and standardized work, provides a unique opportunity to integrate operational excellence with environmental sustainability. The results obtained in our study align with this perspective and reinforce the notion that Lean is not simply a productivity-enhancing methodology but also a framework for sustainable industrial development.

The findings are consistent with the work of Aucasime-Gonzales et al. [8], who reported an 18% improvement in productivity after using Lean tools. Although their study focused on efficiency, better productivity often means less use of materials, energy, and water. In our case, the improvement in efficiency was smaller (1.03%), but in a resource-intensive industry like textiles, even small gains can reduce energy use and waste. For example, fewer defective products mean less fabric wasted and fewer chemicals used.

This link between operational efficiency and environmental sustainability is further underscored by the results of Makwana et al. [7]. Their application of 5S in a plastic machinery manufacturing company led to a 64% increase in productivity. It also helped reduce unnecessary inventory and motion waste, which in turn lowered the environmental burden. In our study, combination of SMED and Standardized Work resulted in a 33.35% reduction in defects. This reduction represents not only a technical success but also an ecological one: fewer defects mean fewer discarded textiles, less solid waste, and a lower demand for raw material replacement.

A similar pattern is observed when comparing our results with those of Amiel-Reategui et al. [5], who documented a 23% reduction in machine downtime. Reduced downtime not only increases productivity but also enhances energy efficiency. Idle machines still consume electricity. Reducing downtime saves energy and lowers emissions. Our project also improved equipment use and reduced non-productive time, which had similar environmental benefits.

The environmental advantages of Lean are also evident in the findings of Jiménez et al. [9], who reported that machine availability increased from 80% to 93% and setup times decreased from 56.25 to 22.30 minutes. In the textile industry, long setups can lead to significant fabric and energy waste. In our case, SMED and Standardized Work shortened these times, helping the company lower its environmental impact and improve working conditions for employees.

The research of Alcazar-Zamora et al. [10] further validates the environmental dimension of Lean Manufacturing, reporting a 25% reduction in waste and better equipment performance after using Lean tools. Waste reduction is one of the clearest environmental benefits of Lean. In our project, reducing defects and organizing processes better led to less textile waste, supporting ideas of recycling and circular economy.

It’s important to note that the level of improvement depends on the specific conditions of each company. Some see large changes, while others make smaller but still valuable progress. In high-energy industries, even small improvements can lead to big reductions in emissions. In industries with high material waste, like textiles, reducing defects and improving material flow has the biggest impact. In our case, the most important results were lower fabric waste and reduced energy use.

The use of Lean tools like 5S, SMED, and Standardized Work helped the company improve its operations while also reducing its environmental impact. These tools led to fewer defects, less downtime, and more efficient use of resources. As a result, the company became more productive and more sustainable at the same time. The changes also made the workplace safer and encouraged more responsible practices. Overall, this shows that it’s possible to improve both efficiency and environmental care together.

Studies carried out on another textile SME provide a useful benchmark for evaluating the results obtained in our project. For instance, Barrientos-Ramos et al. [11] implemented Lean Manufacturing and standardized work practices in a small textile company, achieving an 8% reduction in defect rates and a 32% improvement in lead time. In comparison, our study reported a 33.35% reduction in defects, which is significantly higher than the results typically observed in similar contexts, where reductions often range from 5% to 30%. This indicates that the strategies implemented in our project were particularly effective in addressing quality issues and minimizing material waste, placing our results in a superior range compared to average industry outcomes, and even approaching the threshold that some studies consider exceptional performance. However, in terms of setup time, our 5.82% reduction remains below the levels commonly reported in Lean implementations, where reductions generally range from 20% to 40%. This suggests that while some initial improvements were achieved, there is significant potential for further optimization, especially through deeper SMED application or process redesign. Overall, this comparison suggests that the defect reduction achieved in our case can be considered superior to the average and close to exceptional, while the improvement in setup time is modest and typical of early stage Lean adoption.

6. Conclusion

It is concluded that the development of the state of the art made it possible to clearly identify the main challenges that the company faced prior to the implementation of improvement initiatives. Among these challenges, the reduction of fabric defects in the production process emerged as the most critical issue, directly influencing efficiency, cost structures, and customer satisfaction. By establishing a comprehensive diagnosis, the study provided a solid foundation upon which to design a management model capable of addressing these shortcomings through the integration of Lean Manufacturing tools such as SMED, standardized work, and 5S. This approach highlights the importance of evidence-based decision making in industrial contexts: before any improvement strategy can be applied, it is necessary to understand in detail the weaknesses, inefficiencies, and environmental impacts embedded within the production process. Environmentally, the net impact value improved significantly, from an initial score of -258 to -14, reflecting a substantial reduction in environmental impact.

The 5S tool proved indispensable in tackling disorganization in the workspace, which was identified as a recurring source of inefficiency and waste. Disorganization not only created difficulties in locating tools and materials but also generated unnecessary motion, longer search times, and higher risks of product contamination. By implementing 5S, the company was able to promote sorting, organizing, and cleaning practices that directly influenced both productivity and environmental sustainability. The audit results, showing an overall score increase of 55.10%, provide quantitative evidence of the transformation achieved. Beyond numerical indicators, the 5S program contributed to a cultural change among operators, fostering responsibility, discipline, and awareness regarding resource use. From an environmental perspective, 5S reduced material waste by minimizing the loss or misplacement of raw materials, improved energy efficiency by streamlining workflows, and enhanced occupational hygiene by creating a cleaner and safer workspace. This demonstrates that even organizational tools, when properly applied, have ecological implications by reducing unnecessary consumption and improving the working environment.

In parallel, the application of SMED and standardized work addressed the inefficiencies associated with machine setups and non-value-adding activities. These tools enabled the identification, classification, and reorganization of activities, eliminating unnecessary movements and minimizing setup times. The restructuring of these processes not only improved time efficiency but also allowed for the establishment of pre-controls and standardized steps, thereby reducing variability and human error. This standardization was crucial in addressing the main challenge identified: the high defect rate in fabric production. The reduction of the defect percentage from 2.65% to 1.64% represents a substantial improvement, as it translates into fewer defective products, lower reprocessing rates, and lesser generation of textile waste.

The impact of these improvements was evident at both operational and economic levels. Increased production capacity and defect reduction resulted in an average monthly net profit increase of $1692.55, demonstrating that Lean Manufacturing interventions were not only technically effective but also financially viable.

Another important conclusion is the scalability and adaptability of Lean tools. While the results of this study are specific to the textile sector, the core principles of Lean can be applied across a wide range of small and medium-sized enterprises. Industries such as food processing, furniture manufacturing, and metalworking can benefit from tools like 5S to improve workplace organization, or SMED to reduce setup times between production batches. These methods are accessible, and effective in addressing common inefficiencies, making them ideal for resource-constrained environments. Moreover, by incorporating basic environmental metrics, companies can simultaneously reduce waste and resource use. This study thus offers a practical reference for other SMEs aiming to boost productivity while moving toward more sustainable operations.

It should also be emphasized that the success of Lean initiatives is closely linked to cultural and organizational factors. The positive outcomes reported in this study were possible because operators actively engaged in 5S practices, supervisors supported the standardization of work, and management endorsed the changes. Without this alignment, the improvements would not have been sustainable. This reinforces the notion that sustainability is not only a technical issue but also a social and cultural challenge. Companies that foster a culture of continuous improvement and environmental responsibility are more likely to achieve lasting results.

In conclusion, the integration of 5S, SMED, and standardized work proved to be an effective strategy for addressing the main challenges identified in the textile production process. The improvements achieved—ranging from a reduction in defects to an increase in profitability—demonstrate the multifaceted value of Lean Manufacturing. Beyond the operational and economic benefits, the study underscores the environmental contributions of Lean, showing that reducing waste, lowering defect rates, and optimizing setups are critical not only for competitiveness but also for sustainability. The lessons derived from this case highlight the necessity of adopting Lean as a holistic management philosophy, one that positions efficiency, sustainability, and organizational learning as complementary goals. Moving forward, the company is well positioned to build upon these achievements, incorporating additional environmental management practices and leveraging Lean principles to further align production with sustainable development objectives.

References

[1] Instituto de Estudios Económicos y Sociales, "Industria Textil y Confecciones," IEES-SIN, 2021. [Online]. Available: View Article

[2] B. Harsanto, I. Primiana, V. Sarasi, and Y. Satyakti, "Sustainability innovation in the textile industry: A systematic review," Sustainability, vol. 15, no. 2, p. 1549, 2023. doi: View Article

[3] R. Cespedes-Pino, J. Hurtado-Laguna, I. Macassi-Jaurequi, C. Raymundo-Ibañez, and F. Dominguez, "LEAN Production Management Model based on Organizational Culture to Improve Cutting Process Efficiency in a Textile and Clothing SME in Peru," IOP Conference Series: Materials Science and Engineering, vol. 796, no. 1, p. 012004, 2020. doi: View Article

[4] C. Meza-Cuenca, G. Vargas-Jimenez, and J. Corzo-Chavez, "Production Management Model to Reduce the Percentage of Defectives by Applying Lean Manufacturing Tools in a Textile Sector: A case study," in Proceedings of the 11th World Congress on Mechanical, Chemical, and Material Engineering (ICMIE 2025), 2025. doi: View Article

[5] G. Amiel-Reategui, E. Vargas-Tapia, and G. Viacava-Campos, "Increase the efficiency of the machine production process in textile companies through a model based on TPM and SMED," 20th LACCEI International Multi-Conference for Engineering, Education, and Technology, vol. 1, no. 1, p. 752, 2022. doi: View Article

[6] K. M. Sharma and S. Lata, "Effectuation of Lean Tool '5S' on Materials and Work Space Efficiency in a Copper Wire Drawing Micro-Scale Industry in India," Materials Today: Proceedings, vol. 5, no. 2, pt. 1, pp. 4678-4683, 2018. doi: View Article

[7] A. D. Makwana and G. S. Patange, "Strategic implementation of 5S and its effect on productivity of plastic machinery manufacturing company," Australian Journal of Mechanical Engineering, pp. 1-10, 2019. doi: View Article

[8] P. Aucasime-Gonzales, S. Tremolada-Cruz, P. Chavez-Soriano, F. Dominguez, and C. Raymundo, "Waste elimination model based on Lean Manufacturing and Lean Maintenance to increase efficiency in the manufacturing industry," IOP Conference Series: Materials Science and Engineering, vol. 999, p. 012013, 2020. doi: View Article

[9] A. Jiménez-Ballumbrosio, D. Rodríguez, and P. Castro, "Improvement proposal to increase the availability of machines in the thermoforming line of a plastic industry applying TPM, SMED and Standardized Work tools," in Proceedings of the 2023 9th International Conference on Industrial and Business Engineering (ICIBE 2023), Beijing, China, vol. 1, pp. 394-402, 2023. doi: View Article

[10] P. A. Alcazar-Zamora, A. E. Escalante-Cier, and M. F. Collao-Diaz, "Production model based on Lean Manufacturing and TPM to increase efficiency in a company in the textile sector," in Proceedings of the 3rd LACCEI International Multiconference on Entrepreneurship, Innovation and Regional Development - LEIRD 2023, Virtual Edition, Dec. 4-6, 2023. doi: View Article

[11] N. Barrientos-Ramos, L. Tapia-Cayetano, F. Maradiegue-Tuesta, and C. Raymundo, "Lean manufacturing model of waste reduction using standardized work to reduce the defect rate in textile MSEs," Proceedings of the 18th LACCEI International Multi-Conference for Engineering, Education and Technology (Virtual Edition), pp. 1-8, Jul. 2020. doi: View Article

[12] J. C. Fin, G. Vidor, I. Cecconello, and V. de C. Machado, "Improvement based on standardized work: an implementation case study," Brazilian Journal of Operations & Production Management, vol. 14, no. 3, pp. 388, September 2017. doi: View Article

[13] A. M. Vieira, F. J. Silva, R. D. Campilho, L. P. Ferreira, J. C. Sá, and T. Pereira, "SMED methodology applied to the deep drawing process in the automotive industry," Procedia Manufacturing, vol. 51, pp. 1416-1422, 2020. doi: View Article

[14] P. N. Kuchekar, R. Pant, and R. P. Polampally, "Implementation of 5S methodology in manufacturing industry: Case study," Int. J. Innov. Sci. Res. Technol., vol. 4, no. 5, pp. 1254, May 2019. [Online]. Available: View Article